Now that we’ve explored the farm, and gotten an in-depth look at the long, involved process tobacco goes through on it’s way to becoming a cigar, it’s time for photogenic part of the tour. The part everyone thinks about when they hear “cigar factory tour” – the bunching, rolling and packaging of the finished product. But it isn’t all fun and games, there’s still more sorting and more quality control to be done along the way, as you will see.

Congratulations tobacco, if you make this far into the process, you’re going to be part of a cigar. In an area of the factory Yuri Guillen refers to as “the kitchen” tobacco is carefully weighed and enough blend material is bundled together to create 150 cigars. By weighing and counting leaves, they can be sure that a consistent amount is used in each cigar.

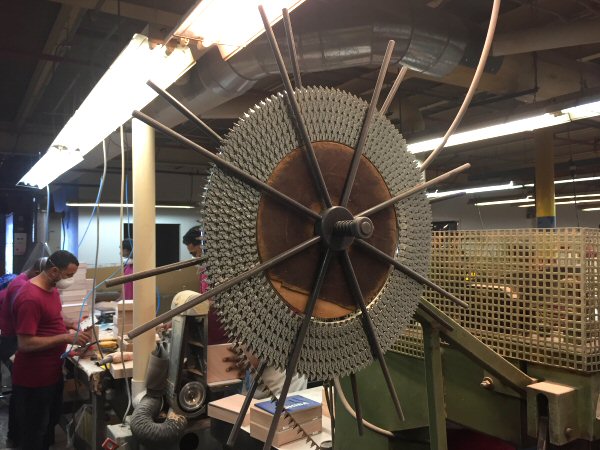

At this point, it’s time for the most photographed and videoed part of making a cigar- bunching and rolling. General Cigar uses a Lieberman machine create their bunches, which allows them to work in teams of three when it comes to producing cigars- two rollers, and one buncher. Actually, if you count the person running the draw-testing machine on each bunch, it’s a team of four. After each cigar is rolled, they are again inspected for size and imperfections.

Things are a little different for La Gloria Cubana cigar lines. They are rolled in a different area of the factory, and the teams are two instead of three. The point is to maintain the distinction of the brand, but also because the cigars are larger and more labor-intensive to produce.

Cigars that pass through the various inspections are off to what Yuri Guillen calls “the money room”. This room is a vast space where approximately two and a half million cigars are held to age for at least three weeks. (Another aging room dedicated to La Gloria Cubana lines holds about 700 thousand.) The goal at this point is for the various components of the blend to properly integrate (or marry) over time, and in the process give off excess moisture (preventing mold growth) and ammonia.

So at this point it’s just a matter of putting cigars in a box, right? Close, but there’s one more round of sorting, or “shading” that is done before that can happen. Cigars are grouped according lightness or darkness of color, to ensure that when you open a box, the cigars you see are consistent in appearance. Additionally, this step of quality control is in place to catch any flaws or damage that may have been missed previously, or may have occurred during transport.

Through a very streamlined process, cigars are banded, cellophaned, UPC’ed and boxed with impressive speed and efficiency. The boxed cigars then spend five days in the deep freeze to eliminate any risk of beetles. This more than a large version of the freezer you have out in the garage. This industrial freezer brings the cigars down to -25°F, and they have seven of them throughout the factory. In order to prevent condensation from forming on the cigars as warm up, they turn the freezer off on the fourth day and allow the cigars to spend a day gradually returning to room temperature.

After checking out the industrial freezer, and then the separate La Gloria Cubana rolling floor and aging room, he had a look at the office of General Cigar’s former master box maker, Paulino Delgado. He is now retired, and the office had been converted to a small museum of his work over his 46 year career with the company.

And that brings us to the end of the second half of the General Cigar factory tour. To see all the action for yourself, hit the play button below. The video runs about 30 minutes, and it covers everything mentioned above. Grab your favorite 30-minute smoke and enjoy!